Turface SAF Trac

Specially Blended Warning Track Aggregates

Turface Athletics® has long been the industry leader in providing quality materials to make fields safe and playable. Our expanded line of warning track aggregates builds on this tradition of trusted performance, offering coaches and groundskeepers products specially designed for the following:

- Aesthetically pleasing appearance

- Superior drainage reduces puddling

- Compacts well to provide firm surface

- Stability provides sure footing for athletes

Turface SAF Trac products are a quality solution for sure footing and minimal dust on warning tracks.

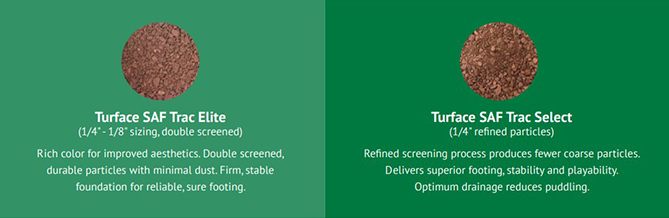

Turface SAF Trac Select - Lightweight and easy to spread, great red color, excellent percolation, and extremely durable. Our refined screening process produces fewer coarse particles allowing for optimum drainage to reduce puddling and provides superior footing, stability and playability.

Turface SAF Trac Elite - Double screened, 1/4" to 1/8" sizing. Rich color for improved aesthetics. Double screened, durable particles with minimal dust. Firm, stable foundation for reliable, sure footing.

Particle Sizes and Color Choices to Meet Your Specific Needs

Turface SAF Trac products are available to ship out of Alabama in bulk truckloads and 2000# sacks.

From Warning Tracks to Walking Paths

Turface SAF Trac products provide solutions in areas where standing water and mud are reoccurring problems. Install this beautiful aggregate on any area with high foot traffic where you want a consistent surface, better drainage, compaction resistance and enhanced aesthetics:

- In front of dugouts

- Walkways between diamonds

- Landscape paths

- Driveways